For industrial manufacturers, the confluence of rising production costs and competitive pressures underscores the importance of trimming expenses without sacrificing quality or safety. Labor costs, being a significant component of operational expenditures, demand careful scrutiny and innovative solutions. Automation technology presents a compelling avenue for cost reduction, streamlining processes and mitigating the need for excessive manpower.

Furthermore, modern scheduling software enables precise workforce management, ensuring optimal staffing levels while minimizing overtime expenses. By embracing these advancements and fostering a culture of continuous improvement, manufacturers can achieve sustainable cost savings while maintaining high standards of workplace safety and efficiency.

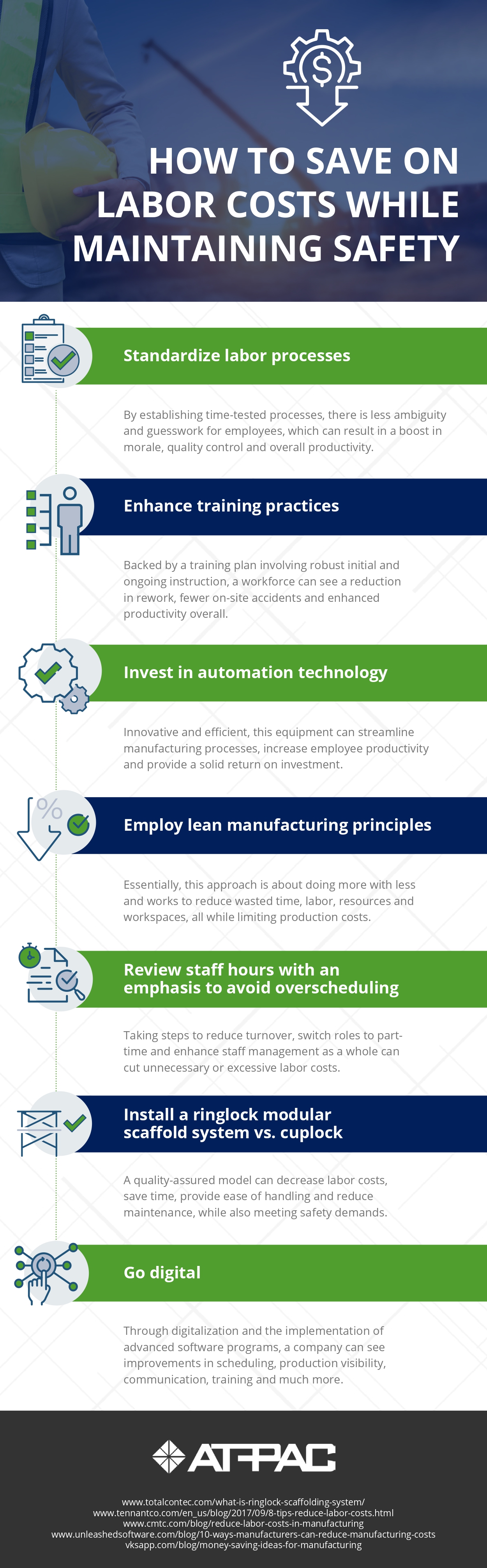

To learn more about how these technologies are improving the efficiency throughout industrial operations, continue on through the infographic supported alongside this post.

How To Save On Labor Costs While Maintaining Safety was provided by Atlantic Pacific Equipment, a scaffolding parts